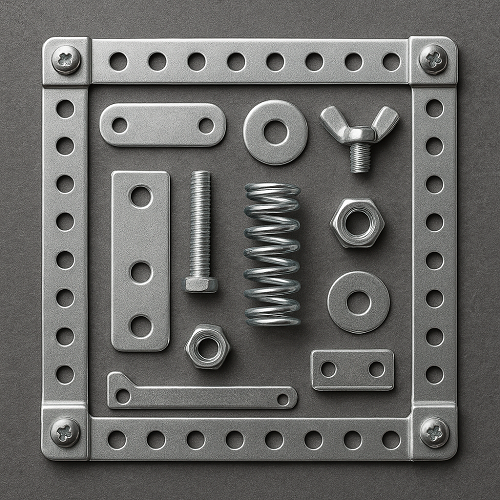

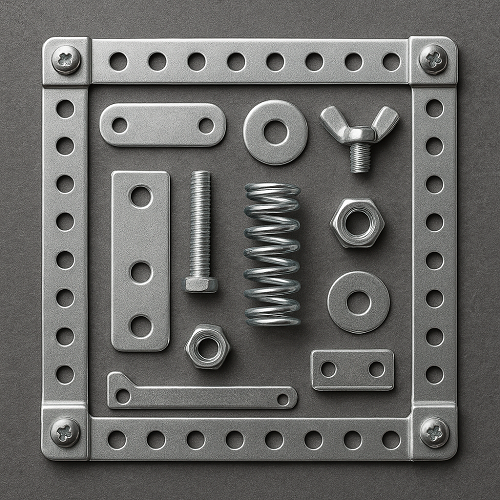

In the world of construction, manufacturing, automotive engineering, and even consumer goods, metal assembling accessories play a vital role in ensuring structural integrity, efficiency, and functionality. These seemingly small components—ranging from bolts and nuts to brackets, hinges, and clamps—are the backbone of mechanical and structural assemblies. Without them, large-scale projects and intricate devices alike would lack reliability and durability.

1. Overview of Metal Assembling Accessories

Metal assembling accessories are auxiliary components designed to join, fix, support, or secure different parts of a structure or mechanism.

Their primary purpose is to:

- Provide mechanical strength to connections.

- Allow ease of disassembly and maintenance.

- Maintain alignment and stability.

- Enhance safety and reliability.

They can be categorized broadly into fastening devices, supporting fixtures, and motion-enabling accessories.

2. Types of Metal Assembling Accessories

2.1 Fasteners

Fasteners are the most common category, designed to hold two or more components together.

- Bolts and Nuts: Provide secure threaded connections; often used in heavy machinery and steel structures.

- Screws: Ideal for applications requiring precision and semi-permanent joints.

- Rivets: Provide permanent connections; commonly used in aerospace and shipbuilding.

- Washers: Distribute load, prevent loosening, and reduce wear.

2.2 Brackets and Supports

- Angle Brackets: Provide corner reinforcement in construction frames.

- Mounting Brackets: Enable attachment of devices like motors or panels.

- Beam Clamps: Connect structural beams without drilling or welding.

2.3 Hinges and Joints

- Butt Hinges: Used in doors and panels for pivoting.

- Ball Joints: Enable rotational and angular movement in mechanical systems.

- Universal Joints: Allow multi-directional torque transmission in shafts.

2.4 Clamps and Couplings

- Hose Clamps: Secure hoses in hydraulic and pneumatic systems.

- Pipe Couplings: Connect fluid-carrying pipes without leakage.

- Quick-Release Clamps: Enable rapid assembly/disassembly in production lines.

2.5 Specialty Accessories

- Threaded Inserts: Provide durable threads in softer metals.

- Locking Devices: Prevent accidental loosening of fasteners (e.g., spring washers, locknuts).

- Anchors: Fix accessories to masonry or concrete surfaces.

3. Materials Used in Metal Assembling Accessories

The choice of material directly affects performance, cost, and durability.

Common materials include:

- Carbon Steel: High strength and affordability, widely used in bolts and nuts.

- Stainless Steel: Corrosion-resistant, ideal for marine, medical, and outdoor applications.

- Aluminum: Lightweight with good corrosion resistance, often used in aerospace.

- Brass and Bronze: Provide conductivity and resistance to wear, suitable for electrical applications.

- Titanium: Lightweight, high-strength-to-weight ratio, excellent for aerospace and defense.

Surface treatments such as galvanizing, zinc plating, anodizing, and powder coating further improve corrosion resistance and aesthetics.

4. Technical Considerations

4.1 Load-Bearing Capacity

Accessories must be designed to withstand static and dynamic loads without failure. Engineers use parameters such as tensile strength, shear strength, and torque capacity to select the right fasteners.

4.2 Corrosion Resistance

Environmental conditions (humidity, saltwater exposure, chemicals) necessitate corrosion-resistant materials and coatings. Stainless steel and galvanized fasteners are common choices.

4.3 Thermal Expansion

Different metals expand at different rates under temperature changes. Selecting compatible materials prevents warping, loosening, or stress fractures.

4.4 Vibration Resistance

In machinery and vehicles, vibration can loosen accessories. Locknuts, spring washers, and thread-locking adhesives are essential for stability.

4.5 Standards and Certifications

Accessories must conform to international standards for safety and compatibility, such as:

- ISO (International Organization for Standardization)

- ASTM (American Society for Testing and Materials)

- DIN (German Institute for Standardization)

- ANSI (American National Standards Institute)

5. Applications Across Industries

5.1 Construction and Infrastructure

- Steel structures (beams, frames, bridges) rely on high-strength bolts and brackets.

- Anchors and clamps are used to secure pipelines and conduits.

5.2 Automotive and Transportation

- Hinges, rivets, and fasteners ensure durability under vibration and thermal stress.

- Ball joints and couplings provide motion control in steering systems.

5.3 Aerospace and Defense

- Lightweight titanium and aluminum fasteners reduce overall aircraft weight.

- Precision rivets ensure permanent, vibration-resistant connections.

5.4 Consumer Electronics and Appliances

- Miniature screws and threaded inserts are critical for smartphones and laptops.

- Hinges allow smooth opening/closing of devices.

5.5 Energy and Utilities

- High-strength clamps secure pipelines in oil and gas industries.

- Corrosion-resistant accessories are vital in offshore wind and solar installations.

6. Common Challenges

- Galvanic Corrosion: Occurs when dissimilar metals contact in corrosive environments.

- Over-Tightening or Under-Tightening: Leads to either deformation or loosening.

- Material Incompatibility: Causes premature wear or structural failure.

- Supply Chain Quality Issues: Non-standard accessories compromise safety and reliability.

7. Best Practices for Selection and Use

- Assess Load Requirements: Match fastener size, grade, and material to structural demands.

- Consider Environment: Choose corrosion-resistant coatings for outdoor or marine use.

- Follow Torque Specifications: Use torque wrenches to avoid under/over-tightening.

- Standardize Components: Reduce complexity by using standardized accessories.

- Regular Inspections: Identify wear, loosening, or corrosion early.

- Documentation and Traceability: Maintain records of certifications and batch numbers.

8. Future Trends in Metal Assembling Accessories

- Smart Fasteners: Integration of sensors to monitor load, vibration, and stress.

- Advanced Materials: Use of composites and alloys with higher strength-to-weight ratios.

- Automation in Assembly: Robot-compatible accessories for faster production.

- Sustainability: Recyclable metals and eco-friendly coatings.

Metal assembling accessories may be small in size, but they are monumental in importance. Their performance determines the safety, reliability, and efficiency of systems across industries—from towering skyscrapers to precision medical devices. With the advancement of materials science, manufacturing processes, and smart technologies, these components are evolving to meet the growing demands of modern engineering. By understanding their types, technical considerations, and best practices, engineers and manufacturers can ensure robust assemblies that stand the test of time.