Metal parts stamping is one of the most versatile and efficient manufacturing processes used in industries ranging from automotive to electronics. It involves transforming flat sheets of metal into specific shapes and sizes using mechanical or hydraulic presses. This process is valued for its precision, cost-effectiveness, and high production speed.

What is Metal Parts Stamping?

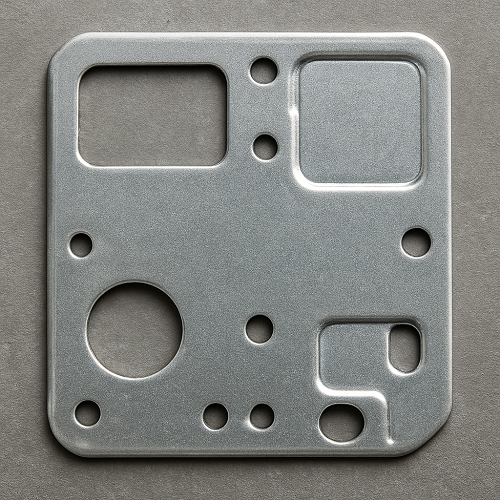

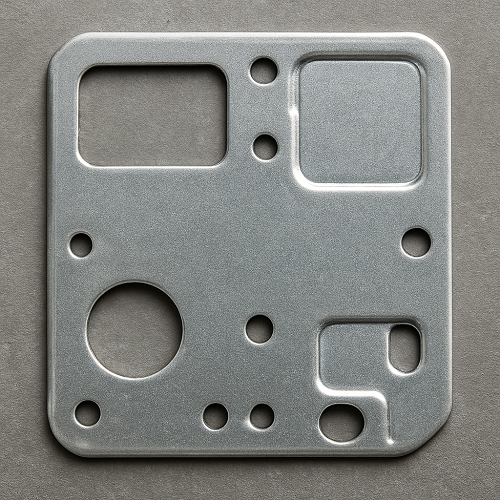

Metal parts stamping is a manufacturing process in which a flat sheet of metal—often referred to as a blank—is fed into a stamping press where it is cut, bent, or shaped into the desired component. Stamping combines a variety of processes, such as punching, blanking, embossing, bending, coining, and flanging, to create complex metal components.

Key Techniques in Metal Stamping

Metal stamping is not a single process but a suite of methods that can be used alone or in combination:

1. Blanking

- The process of cutting flat metal sheets into pre-determined shapes.

- Often the first step in the stamping sequence, providing a base for further operations.

2. Punching

- Involves creating holes in a metal sheet using a punch and die.

- Used extensively in automotive parts, electrical panels, and metal enclosures.

3. Bending

- Metal sheets are bent along a straight line to achieve the desired angle or shape.

- Can range from simple 90-degree bends to complex multi-axis bends.

4. Embossing

- Creates raised or recessed designs on the metal surface.

- Common for logos, serial numbers, or decorative patterns.

5. Coining

- A precision stamping method applying high pressure to achieve fine details.

- Often used for small components like gears, connectors, or coinage.

6. Flanging

- Forms flanges or rims along the edges of metal sheets to strengthen or join parts.

7. Progressive Die Stamping

- Uses a series of dies in one press to perform multiple operations sequentially.

- Ideal for high-volume production with consistent quality.

Materials Used in Metal Stamping

The choice of material depends on the desired properties, application, and cost.

Common materials include:

- Steel: Carbon steel, stainless steel, and alloy steel are widely used for automotive and industrial applications.

- Aluminum: Lightweight, corrosion-resistant, and ideal for aerospace and electronic components.

- Brass and Copper: Excellent for electrical connectors and decorative components.

- Titanium: High-strength, lightweight, and corrosion-resistant; used in aerospace and medical devices.

Each material reacts differently to stamping; factors like ductility, thickness, and tensile strength influence tool design and process parameters.

Equipment and Tooling

Metal stamping relies on specialized equipment:

1. Stamping Presses

- Mechanical presses: High-speed, suitable for medium-sized components.

- Hydraulic presses: Provide consistent force, ideal for thick or hard materials.

- Servo presses: Allow programmable stroke control for precision operations.

2. Dies and Tooling

- Single-Operation Dies: Perform one operation at a time.

- Progressive Dies: Execute multiple operations in a single stroke sequence.

Tool materials include hardened steel, carbide, or coatings like titanium nitride for longer life.

3. Automation & Handling Systems

- Robotic arms, feeders, and conveyors ensure consistent feeding, alignment, and removal of parts.

Advantages of Metal Stamping

- High Production Speed: Ideal for mass production of complex parts.

- Cost-Effective: Less material waste compared to machining.

- Precision: Capable of producing components with tight tolerances.

- Versatility: Works with a wide range of metals and thicknesses.

- Reproducibility: Ensures uniformity across large production batches.

Challenges in Metal Stamping

- Tooling Costs: Initial die design and fabrication can be expensive.

- Material Limitations: Brittle materials can crack during stamping.

- Design Complexity: Very intricate shapes may require multi-step processes or secondary operations.

- Maintenance: Dies and presses require regular maintenance to maintain precision.

Applications of Metal Stamping

Metal stamping finds applications in virtually every industry:

- Automotive: Body panels, brackets, engine components, chassis parts.

- Electronics: Connectors, housings, heat sinks.

- Aerospace: Lightweight structural components.

- Medical Devices: Surgical instruments, implantable components.

- Consumer Goods: Appliances, furniture hardware, decorative items.

Future Trends in Metal Stamping

- Advanced Materials: Increasing use of high-strength steels, aluminum alloys, and composite metals.

- Automation and Robotics: Greater integration for high-speed, low-defect production.

- Digital Twins and Simulation: Reducing trial-and-error in die design.

- Sustainability: Emphasis on material recycling, energy-efficient presses, and waste reduction.

Metal parts stamping is a cornerstone of modern manufacturing, offering unmatched efficiency, precision, and scalability. By understanding the materials, techniques, equipment, and challenges, manufacturers can optimize their stamping processes for quality and cost-effectiveness. As technology advances, metal stamping continues to evolve, integrating automation, advanced materials, and digital tools to meet the demands of modern industries.